NEVADA - RESOURCES

Ziel has increased interest from Nevada cultivators, and we want to highlight the State’s market to illustrate why Radio Frequency, specifically Ziel’s approach, works well with Nevada’s regulatory framework.

Ziel is a leading developer of Radio Frequency (“RF”) equipment for the reduction of microbial pathogens. The food and cannabis industries across North America, Europe, South America, and Australia utilize RF technology to safely remediate products intended for human consumption or ingestion. Ziel’s devices utilize non-ionizing radiation to pasteurize products like almonds, cashews, macadamias, sesame and chia.

The RF technology has been adapted for the cannabis industry to successfully remediate bacterial and fungal pathogens. These devices help Nevada cannabis cultivators ensure that they are providing a safe product that meets the highest safety and quality standards. Moreover, Ziel’s technology allows licensees to satisfy these standards through a method that is compatible with the requirements for organic certification.

Microbiology Test Levels

Nevada has legalized both recreational and medical use since 2017. And is among pioneer states requiring testing of cannabis.

The microbiological requirements for any cannabis flower sold in the state of Nevada are:

- TYMC <10,000 CFU/g

- Total Coliform <1,000 CFU/g

- Enterobacteriaceae <1,000 CFU/g

- Pathogenic coli not detected in 1g

- Salmonella not detected in 1g

- Aspergillus (niger, flavus, fumigatus, terreus) not detected in 1g

- Mycotoxin < 20 ug/Kg of Substance

A common question we hear from cultivators is “Will we pass microbial testing using the APEX 7”. Ziel can assuredly respond that treatment with Radio Frequency is proven to reduce Total Yeast and Mold Count (TYMC) by more than 99.9% and comply with regulatory requirements. Which in Nevada’s case is under 10,000 CFU/g for Medical; a threshold Ziel is very accomplished in meeting. Radio Frequency is also effective in addressing other testing criteria such as Total Aerobic Microbial Count (TAMC), Coliforms, Salmonella and Aspergillus.

While there are various remediation solutions in the market, Ziel’s patented remediation technology using Radio Frequency is becoming the industry standard. The APEX 7 uses Radio Frequency which is a thermal, non-ionizing irradiation process. X-Ray, E-Beam, and gamma

Nevada Cannabis Compliance Board (CCB)

In an effort for greater transparency Governor Sisolak established the Nevada Cannabis Compliance Board (CCB) in 2020, removing it from under the Nevada Tax Commission. Modeled after the NV Gaming Control Board, the CCB Board comprises 5 members appointed by the Governor.

Product Labeling Requirements for Irradiation

The CCB adopted regulation (NCCR) 12.065 in July of 2020. The regulation requires a label with a Radura symbol, along with a notice, be included on cannabis or cannabis products treated with radiation.

Shortly after issuance of 12.065, RAD Source Technologies (RAD), a provider of ionizing radiation, filed a legal claim for $2.4M against CCB for revenues lost due to a previous legal finding.

In November 2020 RAD and CCB reached a settlement in which RAD’s claim for damages was dropped in return for CCB to address 12.065 in a public workshop.

CCB held the public workshop on NCCR 12.065 regarding cannabis and cannabis products treated with radiation on January 19, 2021, chaired by Dr. Bryan Young MD, one of the five Board Members of the CCB. Public comments were filed by RAD, Ziel, and Willow Industries, the three dominant remediation technologies. In addition, several cultivators, dispensaries, and the general public filed public comment.

Ziel wants the CCB to follow FDA guidelines on the use of irradiation and differentiates between ionizing and non-ionizing technologies. The FDA requires the display of the Radura symbol, and specifically calls out that non-ionizing (RF) does not need to display the Radura symbol.

At the XXX 2021 Board meeting, Dr. Young recommended an additional workshop. As of July 2021, no date has been set for the next workshop. Until that time, there is a moratorium on 12.065 going into effect.

Remediation in Nevada

Cultivators in Nevada have had limited options after flower has failed microbial testing. Destruction, retesting, or sending to manufacturing all incurred heavy costs.

On July 27, 2021, the CCB opened a discussion on including remediation as an additional pathway. This could include remediation on-site with an approved technology, as well as sending product out to a third party for processing. Treating product prior to testing, as well as after a failed test would improve consumer safety, reduce cultivator costs, and increase collected taxes.

Financial Returns

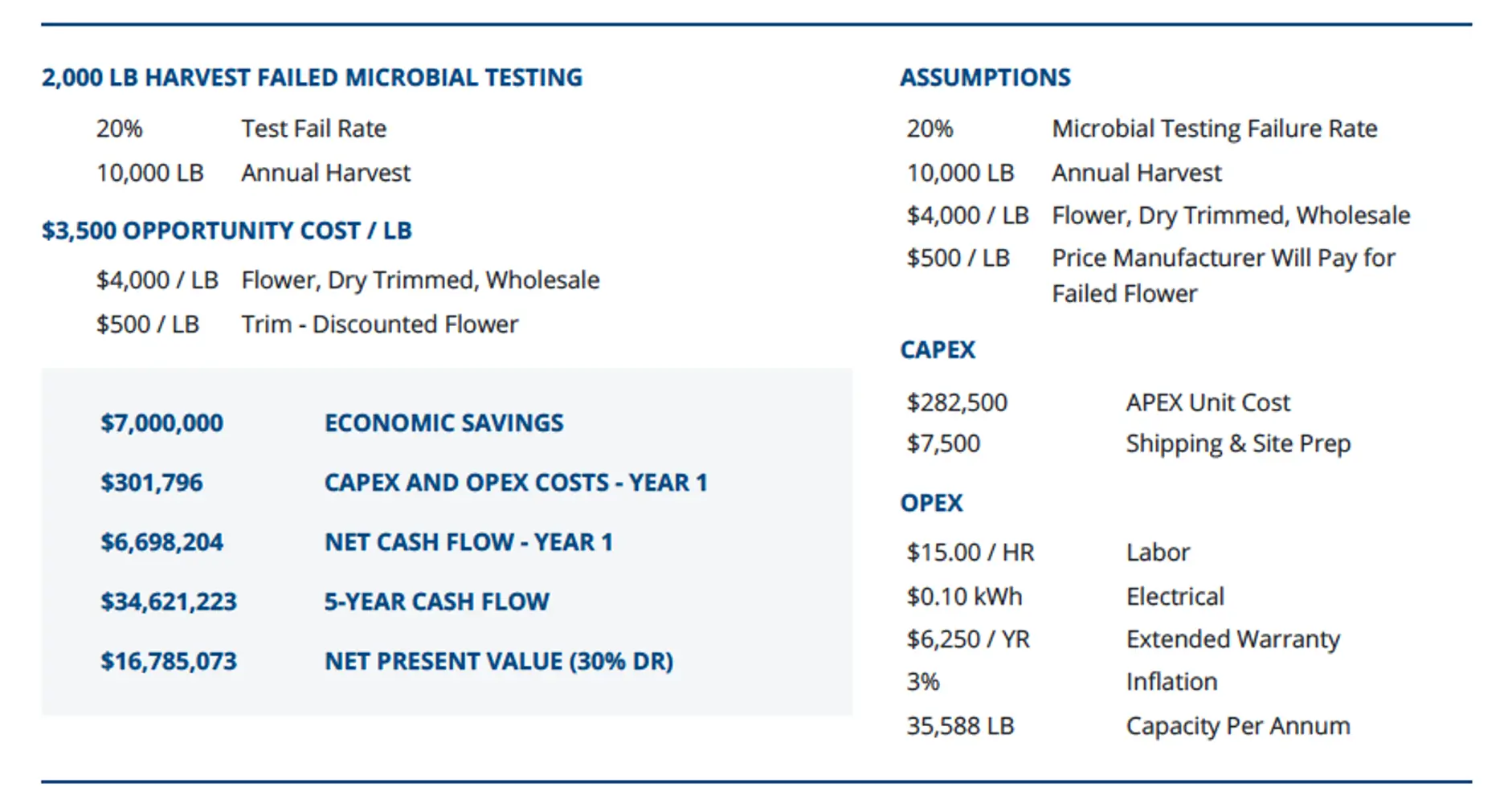

Ziel’s financial calculator allows you to input your own assumptions and determine how much the APEX 7 will save your business remediating your product. The model looks at the percentage of product you are currently failing and bringing that into regulatory compliance. Nevada’s recreational value for 1 LB of flower ranges between $3,500 - $4,500 with trim selling at a deeply discounted price of $500. The snapshot below shows the savings a cultivator will accrue within the first year using the APEX 7.

APEX also has the largest throughput of any technology on the market today, allowing you to scale your business operations.

Clean cannabis technology is a vital safeguard as regulations are only becoming stricter. Ensuring your harvest passes microbial testing increases your top line revenue, and optimizes your financial returns, improving your bottom line. Incorporating remediation into your post-harvest SOPs streamlines operations, avoiding costly retesting, discounting product, and getting your product out the door quicker.

Contact Ziel to learn more about our innovative cannabis processing system for Nevada based growers.