Watch How Radio Frequency Works

Ziel is the industry leader providing next-generation customized solutions that reduce microbial pathogens in cannabis and food products using radio frequency, an organic, non-ionizing thermal process.

With more than 15 years of experience reducing microbial pathogens in an FDA-approved organic process, we are the only remediation solution for cannabis that knows microbiology inside and out.

We ensure cannabis cultivators meet state regulatory compliance with a 99.9% effective pass rate for microbial testing while maintaining the highest product quality.

Why is Radio Frequency the Best Way to Remediate Your Cannabis?

Raise Your Top Line Revenue and Profit

Increasing your yield of flower enables you to sell more of your harvest at the highest value. Bringing a solution in-house eliminates high-cost 3rd party treatment. Ziel's calculator lets you see how to start adding money to your bottom line.

Get Rid of Mold on Cannabis - Fast

Ziel's Apex 7 has the shortest cycle time and highest throughput on the market, up to 3x its competitors.

Preserve and Protect your Brand Identity and Customer’s Health

Avoid negative consumer perceptions and any negative label requirements of ionizing radiation and chemical agents with our thermal process.

Keep Your Cannabis Crops Organic

An FDA-recognized organic solution for food products.

The Longest Warranty in the Industy

We are the only remediation solution providing a bumper to bumper 3- Year warranty. Ziel does not use 3rd party service providers. Should yous system go down, our in-house field service team will be on the phone or on-site.

Get Clean Cannabis

If you have challenges consistently passing testing and want an organic approach that will create customer confidence and won’t impact your product quality, contact Ziel for more information.

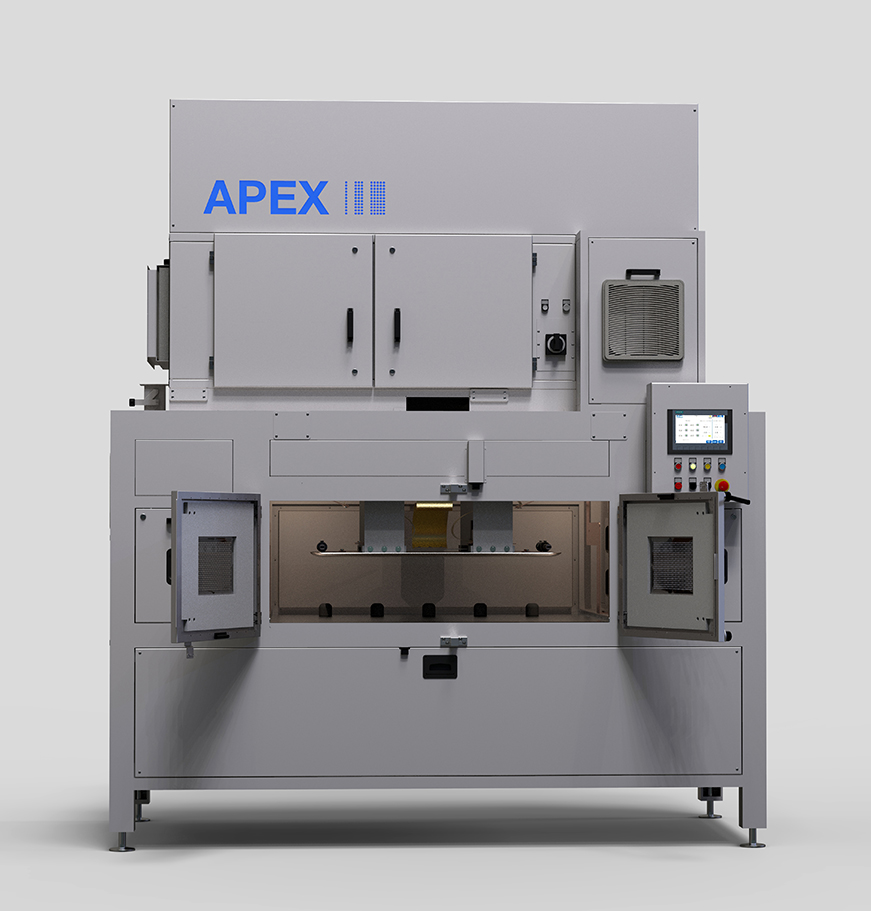

Ziel’s APEX 7 Cannabis Remediation Solution

If you want to increase your passing of microbial testing, improve your financial results, and retain customer loyalty through best practices and an FDA-approved organic technology - you’ve found your solution.

Ziel’s APEX 7 is a scalable solution that will grow as your business grows.

Ziel’s 3-year warranty and turn-key solution includes installation, training, commissioning and ongoing support from our customer success team for your first 6 months to get you in steady state. Working with your team, we monitor performance remotely and analyze your COAs to optimize results through continual engagement.

Financial

Your investment will pay off in months, not years. Our business case is customized for your market conditions and business operations with cash flows and financial metrics that create the necessary buy-in across all your internal stakeholders.

Operations

APEX easily integrates into your facility, with no additional equipment such as chillers. No additional permitting, local approvals, or concerns for your employee's safety. Ziel's online training videos ensure current and future employees have access to best practices.

Quality

All cannabis is not created equal and there is no one approach to reducing microbial pathogens in Cannabis. Ziel, with its roots in food safety, is the only cannabis remediation solution provider on the market that knows microbiology. Our ability to tailor a remediation solution for your product will utilize the minimal remediation solution to pass testing without 'overkilling' your product by reducing the plant's natural enzymatic properties that give your flower its unique aromatic smell and look.

We are certified in Canada as compliant with organic processes in cannabis!

Ziel’s Has the Experience

You’ve worked hard to grow the highest quality product. Don’t throw it away with an overly aggressive remediation solution. Ziel’s APEX uses Radio Frequency, a non-ionizing, chemical-free technology and FDA-approved organic process used for years in the food industry.

We’ve been in the food business for over 15 years and have leveraged that experience into the cannabis industry. We’ve spent the last 6 years validating the efficacy of Radio Frequency for cannabis remediation.

Tailored Cannabis Solutions for Operations of All Sizes

Ziel does not sell equipment. We sell solutions, tailored to each customer based on their starting COAs, and their business goals. Whether it's addressing starting high microbial counts, or scaling your throughput, we have a business solution to meet your needs.

How We Work Together

Installation

Training

Commissioning

Operational Monitoring

Engagement & Improvement

Customer Success

ابق على تواصل معنا

أعرف أكثر

Check out our Resources page and download additional information on the remediation solution you're interested in.

Contact Us Today

Take the first step to boosting your profit margins. Start the conversation now.

Meet the APEX 7

Learn more about how cannabis remediation with the APEX 7 can help your specific operation.