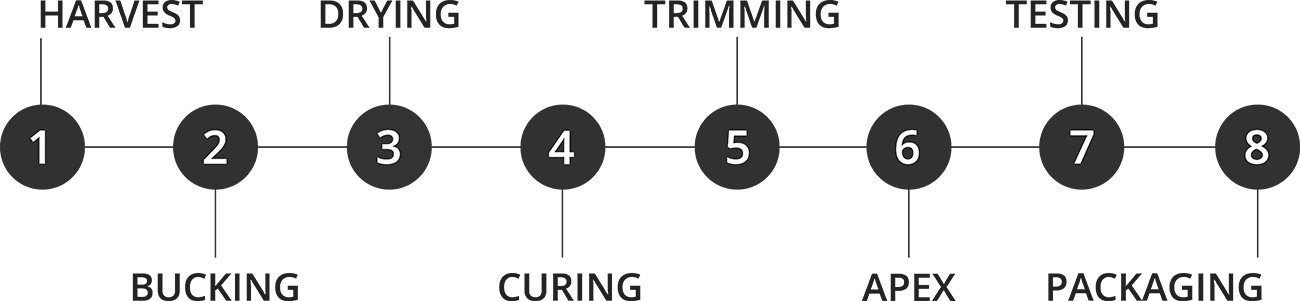

جعل الفشل الميكروبي ليس مشكلة

في الوقت الحالي، يُلحق عفن القنب والخميرة ومسببات الأمراض الميكروبية الأخرى الضرر بأرباحك. زيل قادرة على حل هذه المشكلة.

باستخدام ترددات الراديو غير الضارة (RF)، وهي نفس التقنية المستخدمة في الزراعة منذ عقود لبسترة المكسرات والبذور وغيرها من الأطعمة، يمكننا التخلص من عفن القنب الضار والميكروبات، وضمان امتثال محاصيلكم للأنظمة بنسبة 99.9%. لا مواد كيميائية، ولا أوزون، ولا... الإشعاع المؤين.

انقر على الزر أدناه لمعرفة مقدار الأموال التي يمكنك توفيرها من خلال دمج معالجة القنب في إجراءات التشغيل القياسية الخاصة بك.

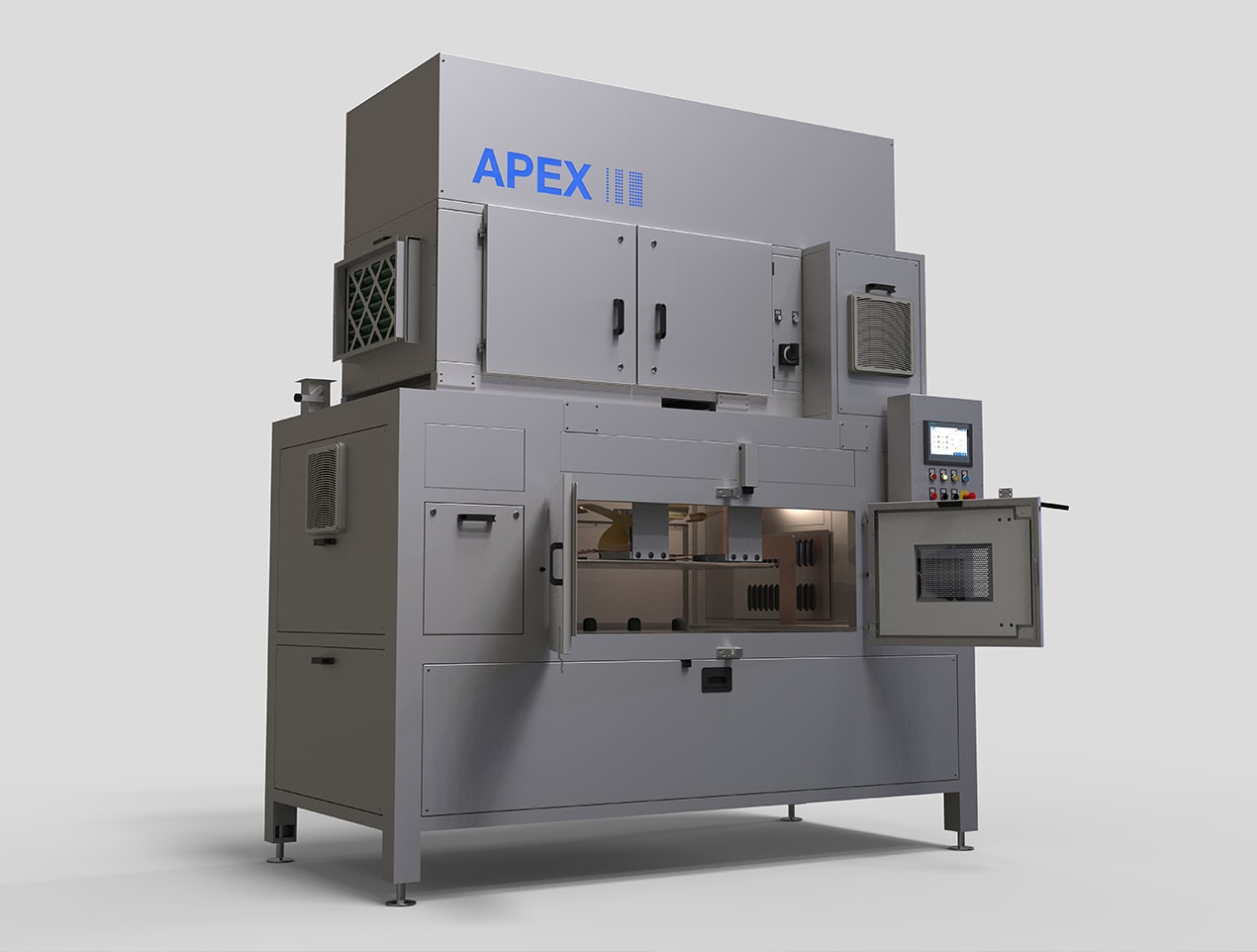

APEX 7

خطوة قتل خالية من المواد الكيميائية مناسبة للعمليات العضوية والمعتمدة من GMP

خالية من الإشعاعات المؤينة والمواد الكيميائية

يعالج الزهور المقصوصة والمطحونة

متوسط وقت الدورة 14 دقيقة

لا يتطلب أي تعديلات على المرافق

يعالج 0.5 - 2.7 كجم/دفعة (1-6 رطل/دفعة)

التركيب والتشغيل والتدريب الجاهز

الحفاظ على الخصائص الأنزيمية الطبيعية للنبات

مناسب للعمليات العضوية

الخسارة الاسمية للتربينات و رُطُوبَة

ما يصل إلى 3 سجل تخفيض مسببات الأمراض الميكروبية

ضاعف حصادك لتعزيز أرباحك

كنا نخفق في اختبار 40% من اختباراتنا الميكروبية. كان إدخال APEX في عملياتنا عام 2018، والشراكة مع Ziel، نقطة تحول. نجري 100% من أزهارنا الفاخرة عبر APEX، ونجتاز اختباراتنا بثقة، ونحافظ على أعلى مستوى من الجودة. مكّنتنا معالجة APEX من تغيير أعمالنا بالكامل، مما زاد حصتنا السوقية وإيراداتنا وأرباحنا.

مارك برونو

المؤسس المشارك لشركة تاهو هيدرو

قوة الترددات الراديوية

الترددات الراديوية غير مؤينة، أي أنها لا تُغير التركيب الجزيئي لزهرة القنب. بل تستخدم أطوالًا موجية راديوية طويلة لإنشاء مجال كهرومغناطيسي متذبذب حول الزهرة وداخلها، يصل إلى لب البرعم. تتزامن جزيئات رطوبة الزهرة مع هذا الاهتزاز وتبدأ بالدوران معه، بمعدل 27 مليون مرة في الثانية. هذا يُولّد احتكاكًا، مما يُولّد في النهاية حرارة كافية لقتل مسببات الأمراض الميكروبية، ولكن ليس حرارة كافية لتحلل أو إزالة رباعي هيدروكانابينول (THC).

تتيح إعدادات العملية الخاصة بشركة Ziel في APEX 7، والتي يتم إدارتها بواسطة نظام Siemens PLC/HMI، التحكم بدقة في الحرارة في الوقت الفعلي عبر مجسات درجة الحرارة، مما يقلل الميكروبات المستهدفة إلى مستويات آمنة دون المساس بقوة الزهرة أو ملف التربين أو الصفات الحسية.

متوسط النتائج مع APEX 7:

في الإيرادات السنوية المستردة

معدل اجتياز الامتثال للاختبارات الميكروبية

من الزهور التي تتم معالجتها يوميا

اجتياز اختبارات المعمل بثقة

يضمن تطبيق إجراءات إعدام القنب قبل إرسال محصولك إلى المختبر نسبة نجاح 99.9%. يُجنّبك ذلك الحاجة إلى إعادة الاختبار المُكلفة، أو تأخير طرح المنتج في السوق، أو الآثار السلبية لفشل المنتج.

الشراكة مع زيل

ابدأ العمليات التجارية مع جهاز APEX 7 الخاص بك خلال أسبوع واحد من التثبيت

عند دمج جهاز APEX 7 في إجراءات التشغيل القياسية، ستحصل أيضًا على فريق من العلماء والخبراء من شركة Ziel تحت تصرفك. نضمن لك إتمام عملية التركيب والتشغيل والتدريب في غضون 4 أيام فقط. ثم نراقب كل دفعة تُجريها خلال السنة الأولى لمساعدتك في تحديد الأنماط، واستكشاف الأخطاء وإصلاحها، وتحسين وصفات علاج القنب الخاصة بك.

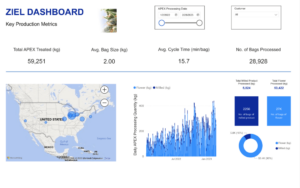

نهج قائم على البيانات

لا يقتصر دور جهاز APEX 7 على معالجة القنب وتطهيره، بل يجمع البيانات من كل دفعة تُنتجها، مما يمنحك فهمًا أعمق لعملك. مع جهاز APEX 7، ستتعلم:

- أي من سلالاتك أكثر عرضة للإصابة بعفن القنب ومسببات الأمراض (نعم، السلالة تحدث فرقًا!)

- ما هي الميكروبات والمسببات للأمراض الأكثر انتشارًا في عملك حتى تتمكن من معالجتها عند المصدر

- كثافة محتوى الرطوبة لكل سلالة

- وصفات علاج القنب الدقيقة التي تحتاجها عمليتك (تحتاج العملية المتوسطة إلى 1-2 وصفة فقط.)

المتطلبات الفنية لبرنامج APEX 7

| تطبيقات المنتج | زهرة القنب والقنب |

| معدل الإنتاج | يعالج 0.5-2.3 كجم/دفعة (1-5 رطل/دفعة) |

| وقت المعالجة | متوسط وقت الدورة 14 دقيقة |

| طاقة التردد اللاسلكي | 7 كيلوواط |

| المتطلبات الكهربائية | 400/480 فولت تيار متردد +/-5%، 3 مراحل + أرضي، 50/60 هرتز، حمل متصل 32/38 أمبير |

| الرموز والمعايير | علامة CE؛ متوافقة مع UL وCSA ومتوافقة مع FCC |

| أبعاد النظام | 2800 مم (طول) × 1520 مم (عرض) × 3110 مم (ارتفاع) 9'-3” (طول) × 5'-0” (عرض) × 10'-3” (ارتفاع) |

| الوزن الإجمالي | 821 كجم / 1810 رطل |

| مواد البناء | هيكل من الفولاذ المقاوم للصدأ بدرجة الغذاء |

| بيئة التشغيل | موقع داخلي، غرفة جيدة التهوية من 15 درجة مئوية إلى 40 درجة مئوية (59 درجة فهرنهايت إلى 104 درجة فهرنهايت) الرطوبة النسبية من 10% إلى 90% بيئة غير مكثفة |

| متوسط العمر المتوقع | معدات هيكلية رئيسية لأكثر من 20 عامًا |

| ضمان | ضمان محدود لمدة عام على قطع الغيار والعمالة الأصلية |

| مصنعة | إيطاليا |

| ضوضاء | <80 ديسيبل |

| تثبيت | <3 أيام |

استكشف جميع منتجاتنا

تقوم شركة Ziel بتصميم وبناء وتثبيت خطوط المعالجة الخاصة بنا مع وضع متطلباتك ومنتجك في الاعتبار.