ترددات الراديو لبذور الشيا

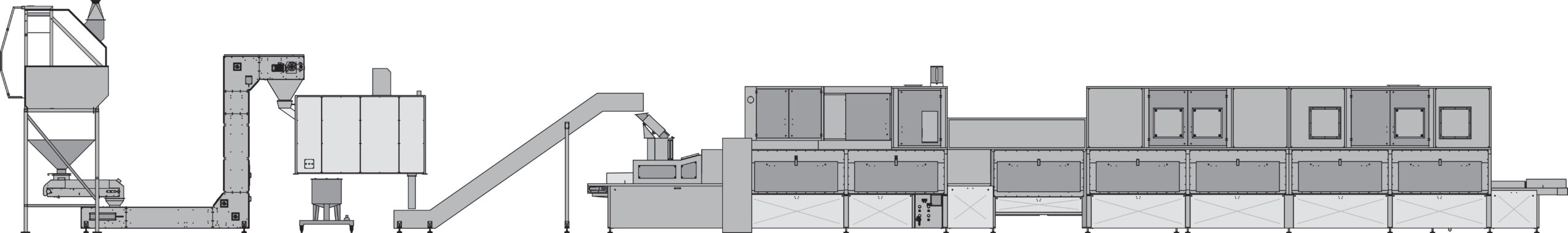

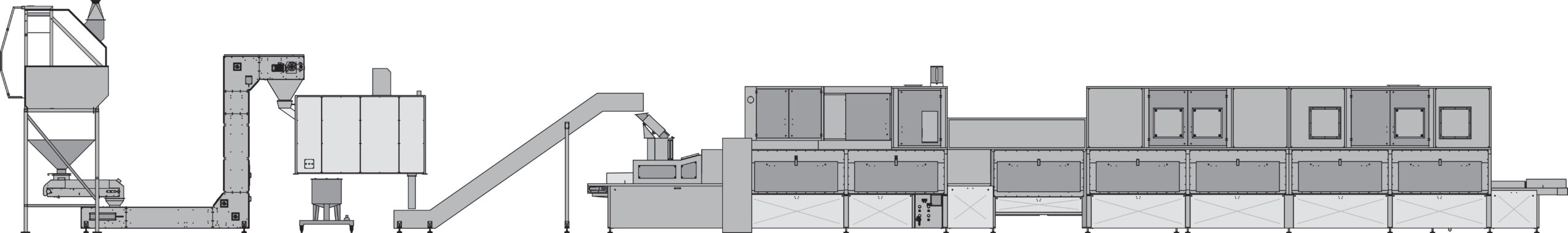

تم تطويره بالشراكة مع STALAM، الشركة الرائدة عالميًا في تكنولوجيا الترددات الراديوية، حيث يعمل APEX 85 على تقليل السالمونيلا من خلال قتل 3 إلى 5 جذوع دون التأثير على الصفات الحسية للمنتج.

خالية من الإشعاعات المؤينة والمواد الكيميائية

يحافظ على السمات الحسية للمنتج

ثبتت فعاليتها في قتل السالمونيلا من 3 إلى 5 جذوع

يعالج ما يصل إلى 725-1200 كجم/ساعة (1600-2700 رطل/ساعة)

مدة العلاج لكل دفعة: 20-30 دقيقة

النظام المستمر

لماذا يعد التردد اللاسلكي أفضل طريقة لتنظيف بذور الشيا؟

- زيادة كفاءة المعالجة والإنتاجية

يوفر جهاز APEX 85 أداء معالجة مستمرًا لا مثيل له، حيث يعالج ما يصل إلى 1100 كجم (2400 رطل) من بذور الشيا في الساعة. - ضمان السلامة والجودة

تعمل تقنية RF من Ziel على القضاء على الميكروبات ومسببات الأمراض، بما في ذلك السالمونيلا والإشريكية القولونية، مما يحقق انخفاضًا يتراوح بين 3 إلى 5 سجلات. - الحفاظ على سلامة المنتج

على عكس الطرق المؤينة أو الكيميائية أو المعتمدة على البخار، فإن جهاز APEX 85 لطيف على بذور الشيا ويحافظ على النكهة والملمس والقيمة الغذائية مع الحفاظ على فقدان الرطوبة أقل من 1%. - إزالة التلوث بشكل مستدام وخالٍ من المواد الكيميائية

لا تتطلب معالجة الترددات الراديوية أي مواد كيميائية قاسية، مما يجعلها حلاً نظيفًا وصديقًا للبيئة لمعالجي بذور الشيا.

محلول APEX 85 لتطهير بذور الشيا

يتكامل جهاز Ziel APEX 85 بسلاسة مع منشأتك ويوفر:

وصفات قابلة للتخصيص

إعدادات مخصصة لتتناسب مع متطلبات المعالجة الخاصة بك.

المراقبة في الوقت الحقيقي

التتبع الآلي لدرجة الحرارة وتقدم الدورة لإزالة التلوث بدقة.

العمليات القابلة للتطوير

تم تصميمه ليتناسب مع نمو أعمالك، بدءًا من الدفعات الصغيرة وحتى المعالجة على نطاق صناعي.

الأسئلة الشائعة حول تطهير بذور الشيا باستخدام Ziel APEX 85

لماذا من الضروري تطهير بذور الشيا؟

بذور الشيا مثل غيرها من السلع الغذائية غالبًا ما تحتوي على حمولة ميكروبية وتحمل مسببات الأمراض مثل السالمونيلا وبكتيريا الإشريكية القولونية من الزراعة والحصاد. يضمن التطهير والبسترة المناسبان سلامة المستهلك، ويحميان القيمة الغذائية لمنتجك، ويحافظان على ثقته من خلال الالتزام بالمعايير التنظيمية الصارمة.

هل يمكن لآلات إزالة التلوث أن تحسن استدامة عملياتي؟

نعم. من خلال تحسين كفاءة المعالجة، يدعم جهاز APEX 85 عمليات مستدامة. يساهم استهلاكه المنخفض للطاقة وتقليله للنفايات في عملية أكثر مراعاةً للبيئة، بينما تضمن الإنتاجية العالية استخدامًا أفضل للموارد.

كيف يتعامل جهاز APEX 85 مع الدرجات أو الأنواع المختلفة من بذور الشيا؟

يتميز جهاز APEX 85 بوصفات معالجة قابلة للتخصيص، مصممة خصيصًا لخصائص ومتطلبات بسترة أنواع مختلفة من البذور. تضمن هذه المرونة نتائج مثالية لمجموعة متنوعة من المنتجات.

هل يعتبر تطهير بذور الشيا ممارسة قياسية في الصناعة؟

نعم. يُعدّ التطهير خطوةً أساسيةً في جميع صناعات إنتاج الأغذية لضمان سلامة وجودة المنتج. في صناعة بذور الشيا، أصبح استخدام آلات مثل APEX 85 معيارًا لتلبية المتطلبات التنظيمية وتقديم منتجات فائقة الجودة.

هل تؤثر عملية RF على الصفات الطبيعية لبذور الشيا؟

لا، تقنية الترددات الراديوية هي تقنية لطيفة وغير مؤينة تحافظ على نكهة وملمس بذور الشيا. بخلاف الطرق الأخرى التي قد تترك بقايا أو تُغير خصائص البذور الطبيعية، يضمن جهاز APEX 85 بقاء البذور أقرب ما يمكن إلى حالتها الأصلية.

ما الذي يميز Ziel's APEX 85 عن المنافسين؟

يستخدم جهاز APEX 85 تقنية RF المتطورة لتقليل الميكروبات، مما يوفر:

- إنتاجية عالية:تقوم بمعالجة ما يصل إلى 1100 كجم (2400 رطل) في الساعة.

- الدقة والاتساق:يضمن إزالة التلوث بشكل موحد دون "الإفراط في معالجة" البذور.

- التوافق العضوي:عملية غير مؤينة وخالية من المواد الكيميائية مناسبة للشهادات العضوية.

- عملية سهلة الاستخدام:وصفات قابلة للتخصيص، ومراقبة في الوقت الحقيقي، وصيانة سهلة.

لماذا الترددات اللاسلكية متفوقة

عندما يقول مستهلكو 55% في الولايات المتحدة إن نهج أمريكا للإنتاج الزراعي يسير على المسار الخطأ ، فإننا نساعدك في الوصول إلى المسار الصحيح منذ عام 2008.