فرکانس رادیویی برای آجیل و دانه ها

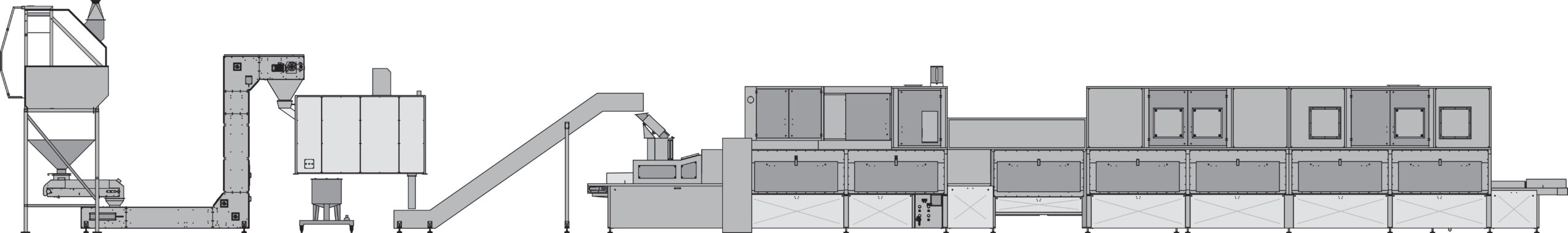

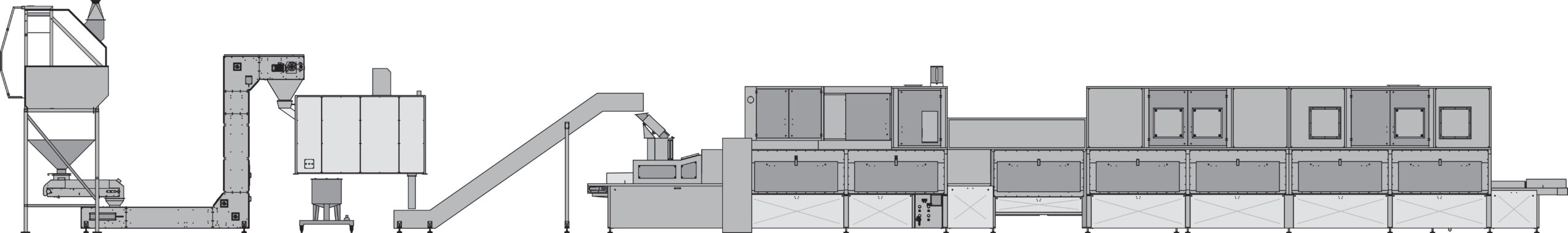

APEX 85 که با همکاری STALAM، رهبر جهانی در فناوری فرکانس رادیویی توسعه یافته است، به طور موثری کاهش می دهد. سالمونلا با یک کشتن 3 تا 5 log بدون تأثیر بر کیفیت حسی محصول.

پرتوهای غیر یونیزان و بدون مواد شیمیایی

ویژگی های حسی محصول را حفظ می کند

3 تا 5 log مرگ ثابت شده برای سالمونلا

تا 725-1200 کیلوگرم در ساعت (1600-2700 پوند در ساعت) را درمان می کند

زمان درمان در هر بسته: 20-30 دقیقه

سیستم پیوسته

3-5 Log Kill Reduction

Apex 85 که با مشارکت پیشرو جهانی در فناوری فرکانس رادیویی STALAM طراحی و تولید شده است، دقت فناوری فرکانس رادیویی را با راه حل های فرآیند اختصاصی Ziel ترکیب می کند تا به طور موثر حذف شود. سالمونلا, E. coliو سایر پاتوژن های میکروبی موجود در آجیل و دانه ها. APEX 85 به راحتی در فرآیندهای خودکار ادغام می شود و به طور موثر پاتوژن های میکروبی را بدون استفاده از مواد شیمیایی، تشعشعات یونیزان یا بخار کاهش می دهد و کاربرد برتر برای محصولات غذایی را ایجاد می کند.

فناوری ما

RF با ایجاد یک میدان الکترومغناطیسی نوسانی بین دو الکترود در محفظه پردازش APEX 85 کار می کند. مولکول های آب قطبی موجود در رطوبت طبیعی محصول که در سطح فرکانس 27.12 مگاهرتز کار می کنند، 27 میلیون بار در ثانیه می چرخند و اصطکاک و در نتیجه گرمای لازم برای از بین بردن پاتوژن های میکروبی ایجاد می کنند. پروفیل موج بلند رادیویی به طور یکنواخت در سراسر محصول نفوذ می کند و برخلاف گرمایش حرارتی سنتی، "گرمای حجمی" ایجاد می کند.

آسان برای کار

رابط کاربری HMI APEX 85 شامل منوهای آسان برای استفاده از دستور العمل های پردازش از پیش برنامه ریزی شده است که توسط Ziel در محل با تیم شما ایجاد شده است. این سیستم پیشرفت و دمای هر درمان را برای ارائه بازخورد در زمان واقعی کاربر نظارت می کند. گزارش های داده به طور خودکار تولید می شوند تا به نظارت و گزارش گیری کنترل کیفیت کمک کنند. نظارت از راه دور اختیاری و ارتقاء نرم افزار از طریق اتصال استاندارد اینترنت در دسترس هستند.

الزامات فنی

| برنامه های کاربردی محصول | آجیل و دانه ها |

| ظرفیت پردازش | تا 725-1200 کیلوگرم در ساعت (1600-2700 پوند در ساعت) * |

| قدرت RF | 85 کیلو وات |

| آب شستشو | حداکثر 60 گالن در دقیقه |

| آب سرد | 23 درجه سانتیگراد (75 درجه فارنهایت) آب، 20 تن (40000 پوند) تبرید |

| زمان پردازش RF | زمان درمان در هر بسته: 20-30 دقیقه |

| الزامات برق | 400/480 VAC +/- 5% | 50/60 هرتز | 3 فاز + زمین | ~500/430 بار متصل |

| کدها و استانداردها | علامت CE؛ مطابق با UL و CSA مطابق با FCC |

| ابعاد سیستم | 21.9 متر (طول) × 2.4 متر (غرب) × 3.3 متر (ط) 72 دقیقه (طول) × 8 دقیقه (غرب) × 11 دقیقه (ط) روز |

| هوای فشرده | به هوای فشرده تمیز، خشک و بدون روغن در ۷ بار (دقیقه) نیاز دارد. |

| سیستم پایه استاندارد | قیف ورودی، فلزیاب، ژنراتور(های) RF، بخش نگهداری و خنک کننده محصول، چیلر برای خنک کننده ژنراتور RF، سیستم نظارت از راه دور (EWON) و SCADA |

| رعایت مقررات | اجزای درجه مواد غذایی در تمام مناطق تماس با کالا |

| ساخت و ساز مواد | سطوح تماس محصول فولاد ضد زنگ درجه مواد غذایی، با ساختار پشتیبانی فولادی رنگ شده |

| محیط عملیاتی | مکان داخلی، اتاق با تهویه خوب 15 درجه سانتی گراد تا 40 درجه سانتی گراد (59 درجه فارنهایت تا 104 درجه فارنهایت) رطوبت نسبی: 10% تا 90% محیط غیر متراکم |

| تجهیزات دیگر | بخش پیش مرطوب - بستگی به محصولی دارد که باید درمان شود |

| گارانتی | 1 سال قطعات و کار محدود |

| تولید شده است | ایتالیا |

تمام محصولات ما را کاوش کنید

Ziel خطوط پردازش ما را با توجه به نیازها و محصول شما طراحی، ساخت و نصب می کند. ما برای طراحی و ساخت سیستم های فرآیند سفارشی که به بهترین نحو اهداف شما را برآورده می کند، با شما همکاری خواهیم کرد.

با ما در تماس باشید

بیشتر بدانید

صفحه منابع ما را بررسی کنید و اطلاعات اضافی در مورد راه حل اصلاحی مورد نظر خود را دانلود کنید.

امروز با ما تماس بگیرید

اولین قدم را برای افزایش حاشیه سود بردارید. اکنون گفتگو را شروع کنید.

با APEX 7 آشنا شوید

درباره اینکه چگونه اصلاح حشیش با APEX 7 می تواند به عملیات خاص شما کمک کند، بیشتر بیاموزید.