High Volume Disinfestation System

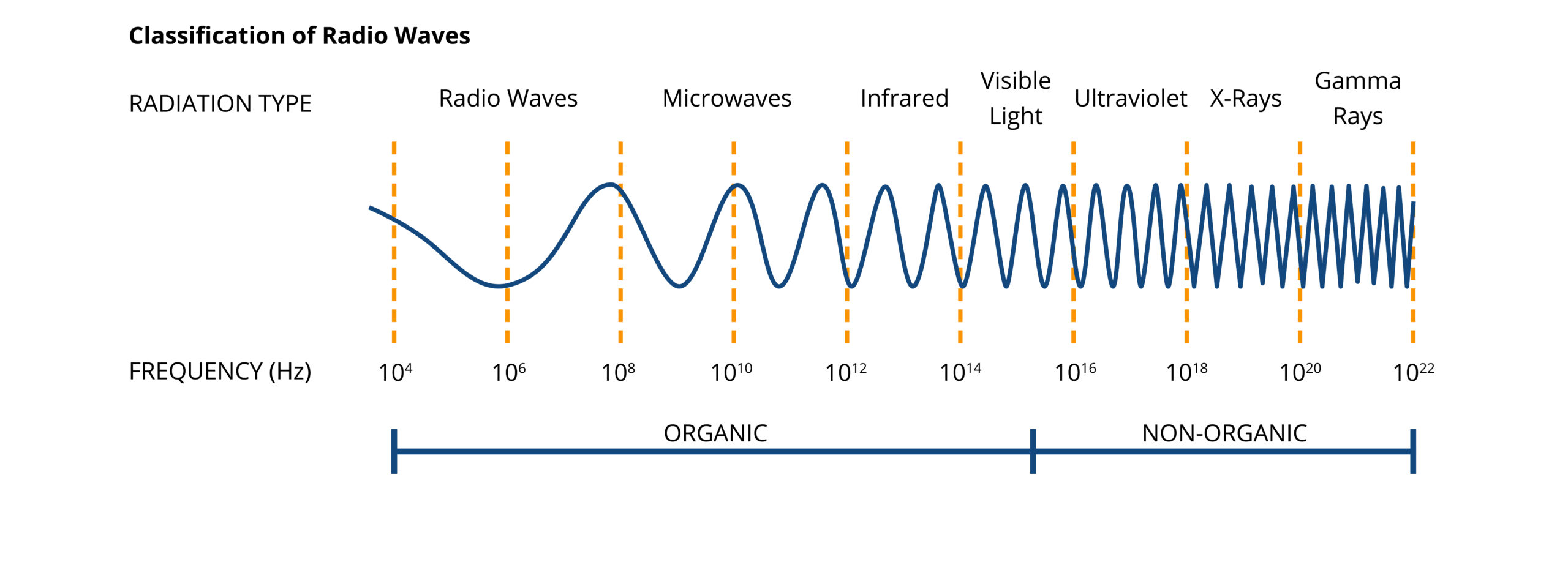

Volumetric heating is the key to success using Microwave for disinfestation or disinfection, because the thermal impact on the entire mass of a commodity is uniform, the time required to reach the critical temperatures to disinfest or disinfect is much lower than conventional heating sources. This lends to higher throughput and less degradation to the product during the thermal process. Microwaves are “non-ionizing, meaning they don’t affect the product on the molecular level as ionizing waves (x-ray or gamma) do by stripping electrons from atoms.

Why Microwave Technology?

Because Microwaves mainly heat materials that contain active water molecules, microwave can be used to treat product inside of packaging, such as cardboard boxes or plastic packaging. The SENTINEL systems can treat loose bulk commodities such as dates or prunes directly on a conveyor belt, or if desired, it can be treated in bulk packaged boxes or bags. Microwave technology is a USDA recognized organic process because it is chemical free, the chemical free process is ideal for growers or producers who strive to provide an Organic product to its customers or consumers, which is an exploding trend in the food and agricultural industry.

Features

- Scalability, easily increase capacity with bolt on chambers & generators

- High output microwave generators with low maintenance components

- Complete stainless steel construction, wash-down rated

- Allen Bradley Control Package with HMI

- High level of automation capabilities E.g. Vision cameras for load monitoring

Benefits

- Volumetric heating

- Organic process

- Yeast and mold reduction and disinfestation capabilities

- High throughput capabilities

- Suitable for product with higher moisture >15%

- Volumetric heating

How Microwave Heating Works

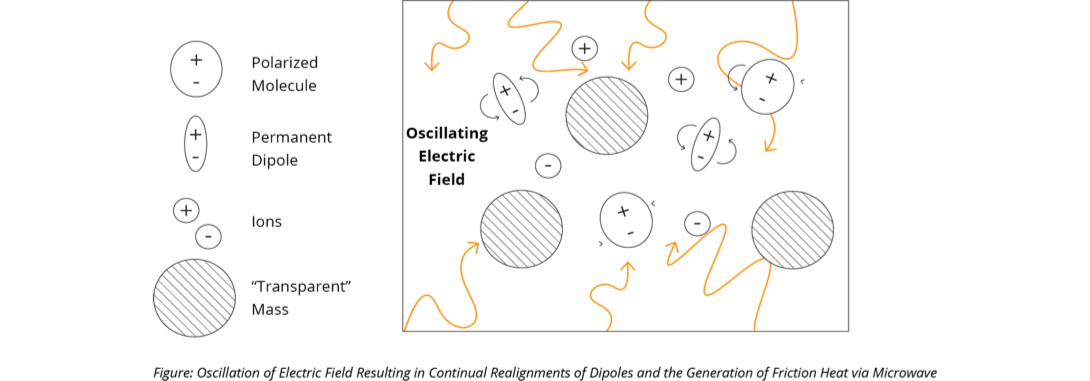

Microwaves generate heat within a commodity by oscillating its water molecules causing friction, this friction results in heating. This is done volumetrically, meaning the entire mass of a commodity is heated at the same time. With conventional heating, such as conductive heat, which relies on the outer layers heating and contacting the inner layers to transfer that heat. This results is overheating or burning of part of the commodity while the inner layers remain cooler. Microwaves are generated from a high powered Magnetron in the Generator assembly, the microwaves are then fed through waveguides to the chamber where the product is passed, microwaves reflect off of the stainless steel chamber and are absorbed into the product.

Explore all our products

Ziel designs, builds and installs our processing lines with your requirements and product in mind. We will partner with you to design and build custom process systems that will best meet your goals.

Get in Touch with Us

Learn More

Check out our Resources page and download additional information on the remediation solution you're interested in.

Contact Us Today

Take the first step to boosting your profit margins. Start the conversation now.

Meet the APEX 7

Learn more about how cannabis remediation with the APEX 7 can help your specific operation.