มิชิแกน - ทรัพยากร

Ziel ได้รับความสนใจมากขึ้นจากผู้เพาะปลูกในมิชิแกน และเราต้องการเน้นย้ำถึงตลาดของรัฐเพื่อแสดงให้เห็นว่าเหตุใด Radio Frequency โดยเฉพาะแนวทางของ Ziel จึงสามารถทำงานร่วมกับกรอบการกำกับดูแลของมิชิแกนได้ดี

Ziel เป็นผู้พัฒนาชั้นนำของความถี่วิทยุ (“อาร์เอฟ”) อุปกรณ์สำหรับลดปริมาณเชื้อก่อโรคจุลินทรีย์ อุตสาหกรรมอาหารและกัญชาทั่วทั้งอเมริกาเหนือ ยุโรป อเมริกาใต้ และออสเตรเลียใช้เทคโนโลยี RF เพื่อแก้ไขผลิตภัณฑ์ที่มุ่งเป้าไปที่การบริโภคหรือรับประทานของมนุษย์อย่างปลอดภัย อุปกรณ์ของ Ziel ใช้รังสีที่ไม่แตกตัวเป็นไอออนเพื่อพาสเจอร์ไรส์ผลิตภัณฑ์ เช่น อัลมอนด์ มะม่วงหิมพานต์ มะคาเดเมีย งา และเจีย

เทคโนโลยี RF ได้รับการปรับให้เหมาะกับอุตสาหกรรมกัญชาเพื่อแก้ไขแบคทีเรียและเชื้อราที่ก่อโรคได้อย่างประสบความสำเร็จ อุปกรณ์เหล่านี้ช่วยให้ผู้ปลูกกัญชาในมิชิแกนมั่นใจได้ว่าพวกเขากำลังจัดหาผลิตภัณฑ์ที่ปลอดภัยซึ่งตรงตามมาตรฐานความปลอดภัยและคุณภาพสูงสุด นอกจากนี้ เทคโนโลยีของ Ziel ยังช่วยให้ผู้ได้รับอนุญาตสามารถตอบสนองมาตรฐานเหล่านี้ได้ด้วยวิธีการที่เข้ากันได้กับข้อกำหนดสำหรับการรับรองออร์แกนิก

รัฐมิชิแกนได้ออกกฎหมายให้ใช้ทั้งเพื่อการพักผ่อนหย่อนใจและทางการแพทย์ แต่ได้กำหนดเกณฑ์การผ่านจุลินทรีย์ไว้แตกต่างกันสำหรับแต่ละส่วน ณ วันที่ 1 กรกฎาคม 2021:

ข้อจำกัดเพื่อการพักผ่อนหย่อนใจสำหรับดอกกัญชา เชค ทริม และคีฟ:

- TYMC <100,000 CFU/กรัม

- โคลิฟอร์มทั้งหมด <1,000 CFU/g

- ไมโคทอกซิน < 20 ไมโครกรัมต่อสาร 1 กิโลกรัม

- (สเทค) อีโคไล ไม่ตรวจพบใน 1g

- ซัลโมเนลลา ไม่ตรวจพบใน 1g

- แอสเปอร์จิลลัส (ไนเจอร์, ฟลาวัส, ฟูมิกาทัส, เทอร์เรียส) ไม่ตรวจพบใน 1g

ขีดจำกัดทางการแพทย์สำหรับดอกกัญชา เขย่า และตัดแต่ง:

- TYMC <10,000 CFU/กรัม

- โคลิฟอร์มทั้งหมด <1,000 CFU/g

- ไมโคทอกซิน < 20 ไมโครกรัมต่อสาร 1 กิโลกรัม

- (สเทค) อีโคไล ไม่ตรวจพบใน 1g

- ซัลโมเนลลา ไม่ตรวจพบใน 1g

- แอสเปอร์จิลลัส (ไนเจอร์, ฟลาวัส, ฟูมิกาทัส, เทอร์เรียส) ไม่ตรวจพบใน 1g

ในฤดูใบไม้ผลิของปี 2021 หน่วยงานกำกับดูแลกัญชาแห่งมิชิแกน (MRA) ได้ยุติวิธีการทดสอบ qPCR สำหรับ TYMC และโคลิฟอร์ม โดยกำหนดให้ห้องปฏิบัติการต้องใช้เทคนิคการเพาะเชื้อเป็นมาตรฐานในการทดสอบ ส่งผลให้ผู้ปลูกหลายรายที่เคยผ่านการทดสอบจุลินทรีย์มาก่อนล้มเหลวมากขึ้น

ผู้ปลูกกัญชาในมิชิแกนมีทางเลือกไม่กี่ทางเมื่อต้องเผชิญกับดอกไม้ที่ไม่ผ่านการทดสอบ ดอกกัญชาที่ปนเปื้อนสามารถแปรรูปเป็นสารสกัดได้ ซึ่งจะลดมูลค่าการขายส่งของผลิตภัณฑ์ หรืออีกทางหนึ่งคือ ปรับปรุงดอกกัญชาด้วยเทคโนโลยีที่ได้รับการรับรอง เช่น คลื่นความถี่วิทยุ

เหตุผลประการหนึ่งที่ทำให้กรอบการกำกับดูแลของมิชิแกนมีความพิเศษก็คือพวกเขามีตลาดเพื่อการพักผ่อนหย่อนใจและทางการแพทย์ คำถามทั่วไปที่เราได้ยินจากผู้เพาะปลูกคือ "เราจะผ่านการทดสอบจุลินทรีย์โดยใช้ APEX 7 หรือไม่" Ziel สามารถตอบสนองได้อย่างมั่นใจว่าการรักษาด้วยคลื่นความถี่วิทยุได้รับการพิสูจน์แล้วว่าสามารถลดจำนวนยีสต์และเชื้อราทั้งหมด (TYMC) ได้มากกว่า 99.9% และเป็นไปตามข้อกำหนดด้านกฎระเบียบ ซึ่งในกรณีของมิชิแกนนั้นต่ำกว่า 10,000 CFU/g สำหรับทางการแพทย์ ซึ่ง Ziel ถือว่าบรรลุเกณฑ์ได้อย่างดี นอกจากนี้ คลื่นความถี่วิทยุยังมีประสิทธิภาพในการแก้ไขเกณฑ์การทดสอบอื่นๆ เช่น จำนวนจุลินทรีย์แอโรบิกทั้งหมด (TAMC), แบคทีเรียแกรมลบที่ทนต่อน้ำดี (BTGN), โคลิฟอร์ม ซัลโมเนลลา และ เชื้อราแอสเปอร์จิลลัส.

แม้ว่าจะมีโซลูชันการแก้ไขปัญหาต่างๆ ในตลาด แต่เทคโนโลยีการแก้ไขปัญหาที่ได้รับสิทธิบัตรของ Ziel ที่ใช้คลื่นความถี่วิทยุกำลังกลายเป็นมาตรฐานอุตสาหกรรม APEX 7 ใช้คลื่นความถี่วิทยุซึ่งเป็นกระบวนการฉายรังสีความร้อนที่ไม่ก่อให้เกิดไอออน รังสีเอกซ์ ลำแสงอี และรังสีแกมมาล้วนเป็นเทคโนโลยีสร้างไอออนที่ใช้พลังงานสูงเพื่อเปลี่ยนผลิตภัณฑ์ในระดับโมเลกุล การใช้เทคโนโลยีสร้างไอออนเพื่อแปรรูปกัญชาจะทำให้คุณไม่มีสิทธิ์อ้างสิทธิ์ผลิตภัณฑ์ออร์แกนิก ลูกค้าของเราเลือกที่จะใช้ APEX 7 เนื่องจากคลื่นความถี่วิทยุเป็นกระบวนการที่อ่อนโยน ปลอดภัยสำหรับผู้ใช้และผู้ปฏิบัติงาน และได้รับการสนับสนุนจากบริการลูกค้าของ Ziel

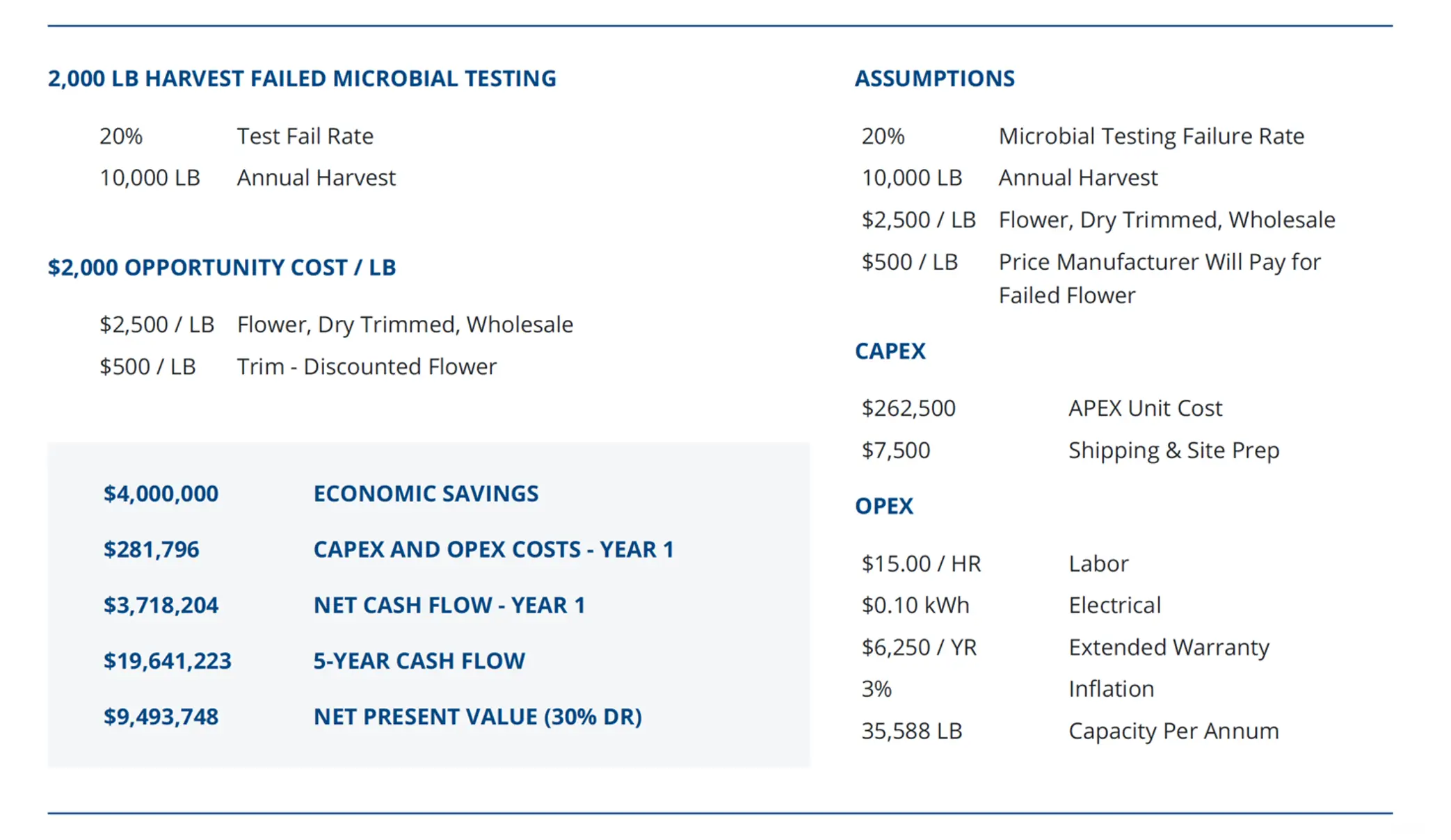

ของเซียล เครื่องคิดเลขทางการเงิน ช่วยให้คุณสามารถป้อนสมมติฐานของคุณเอง และกำหนดได้ว่า APEX 7 จะช่วยธุรกิจของคุณประหยัดได้มากเพียงใดจากการแก้ไขผลิตภัณฑ์ของคุณ โมเดลนี้พิจารณาจากเปอร์เซ็นต์ของผลิตภัณฑ์ที่คุณกำลังล้มเหลวในปัจจุบัน และนำไปปฏิบัติตามกฎระเบียบ มูลค่าการพักผ่อนหย่อนใจของมิชิแกนสำหรับดอกไม้ 1 ปอนด์อยู่ระหว่าง $2,500 - $3,000 โดยการขายตัดแต่งจะลดราคาเหลือ $500 ภาพรวมด้านล่างแสดงการประหยัดที่ผู้เพาะปลูกจะได้รับภายในปีแรกที่ใช้ APEX 7

นอกจากนี้ APEX ยังมีปริมาณงานสูงสุดเมื่อเทียบกับเทคโนโลยีอื่นๆ ในตลาดปัจจุบัน ช่วยให้คุณสามารถปรับขนาดการดำเนินธุรกิจของคุณได้

เทคโนโลยีกัญชาที่สะอาดถือเป็นมาตรการป้องกันที่สำคัญ เนื่องจากกฎระเบียบต่างๆ เริ่มเข้มงวดมากขึ้น การรับรองว่าผลผลิตของคุณผ่านการทดสอบจุลินทรีย์จะช่วยเพิ่มรายได้รวมของคุณ และเพิ่มผลตอบแทนทางการเงินของคุณให้สูงสุด ส่งผลให้ผลกำไรสุทธิของคุณดีขึ้น การนำการแก้ไขปัญหาไปปรับใช้ใน SOP หลังการเก็บเกี่ยวจะช่วยให้การดำเนินงานคล่องตัวขึ้น หลีกเลี่ยงการทดสอบซ้ำที่มีต้นทุนสูง ลดราคาผลิตภัณฑ์ และทำให้ผลิตภัณฑ์ของคุณออกสู่ตลาดได้เร็วขึ้น

ติดต่อทีมงาน Ziel เพื่อเรียนรู้เพิ่มเติมเกี่ยวกับระบบการแปรรูปกัญชาเชิงนวัตกรรมสำหรับผู้ปลูกในมิชิแกน